Accessories and Options

Marcolin Covering provides a comprehensive range of accessories to enhance product functionality across all sectors, including quarrying and construction, agriculture and waste handling. Maximum versatility and customisation for every configuration.

Retractable covering systems

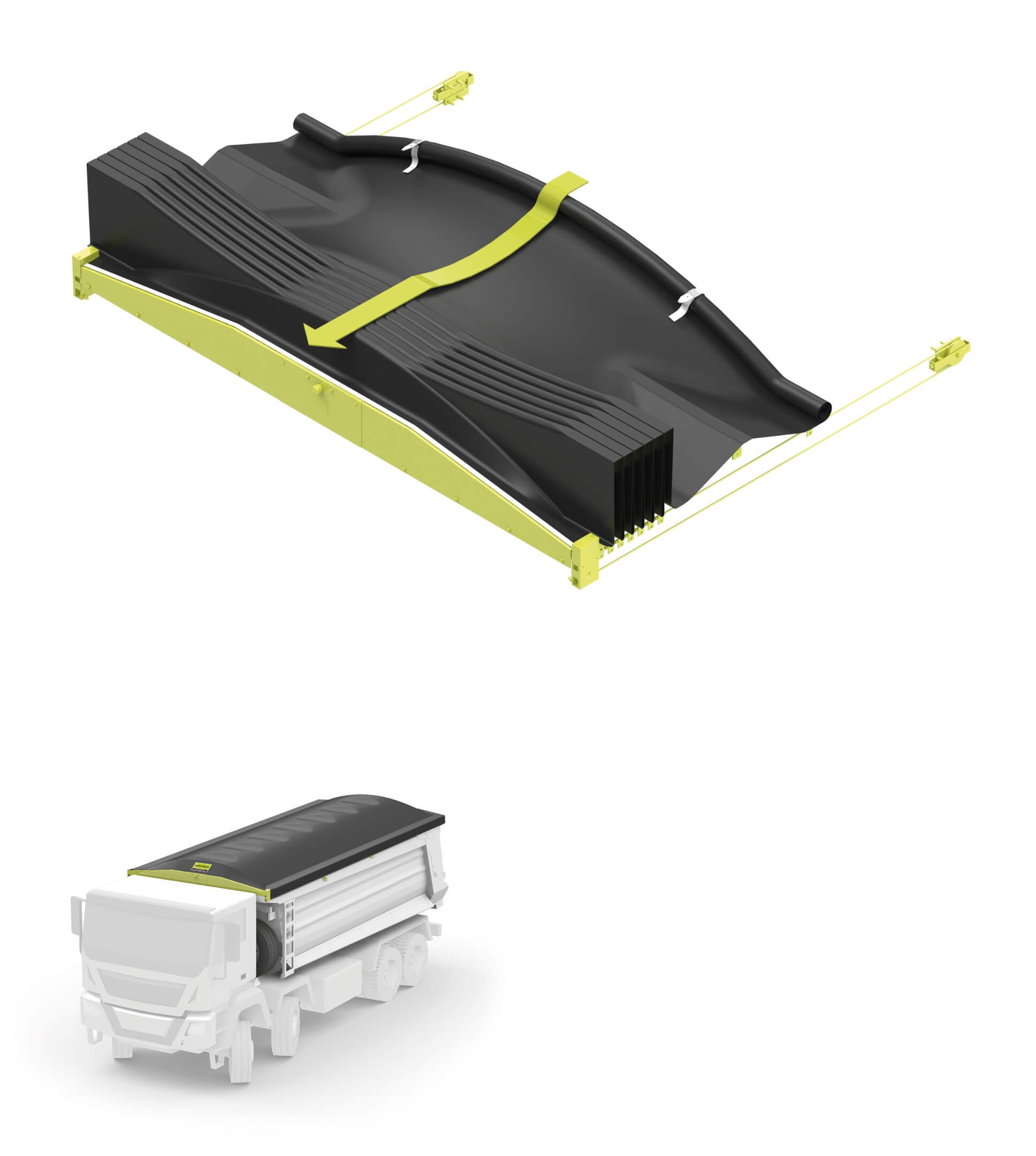

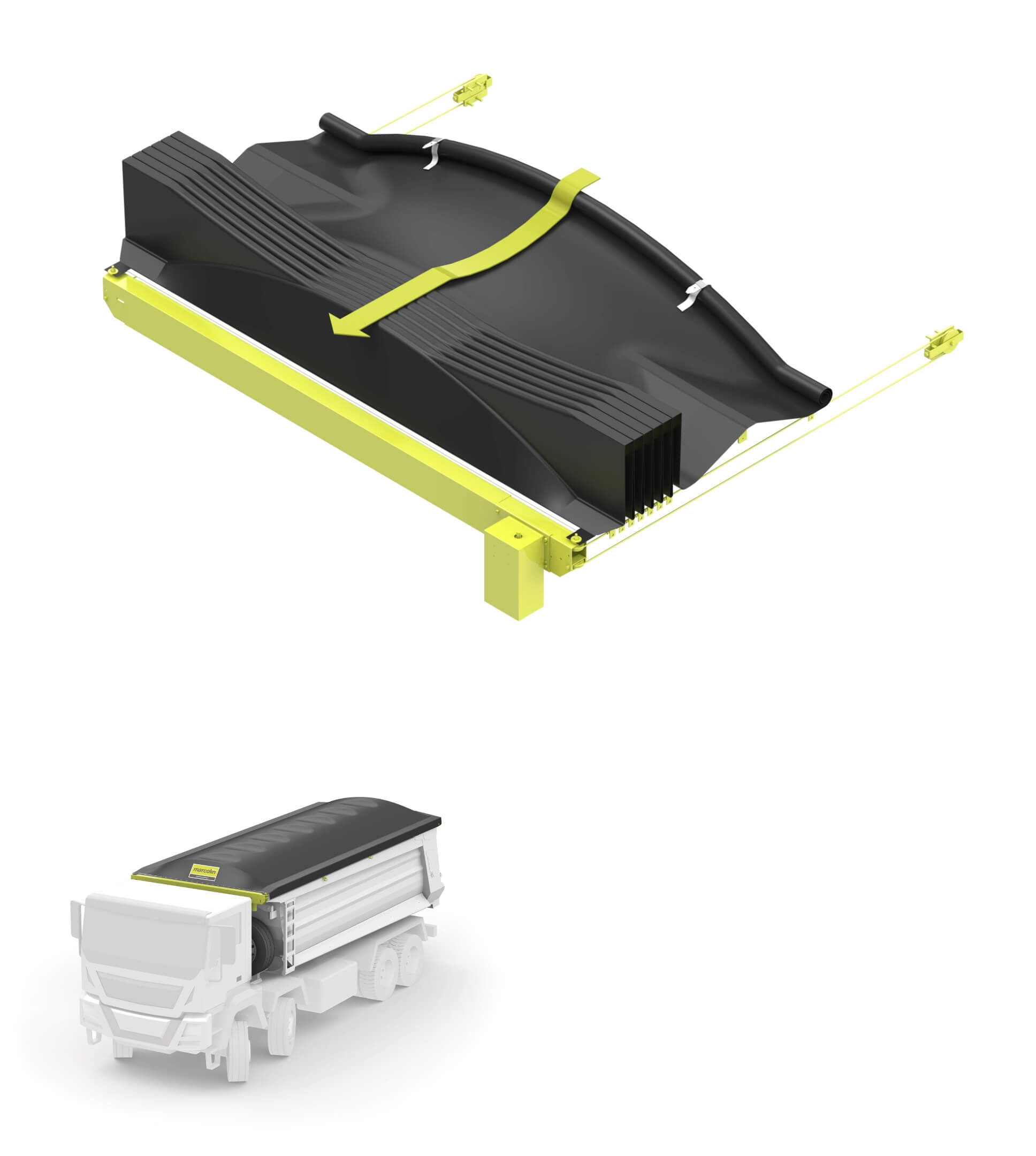

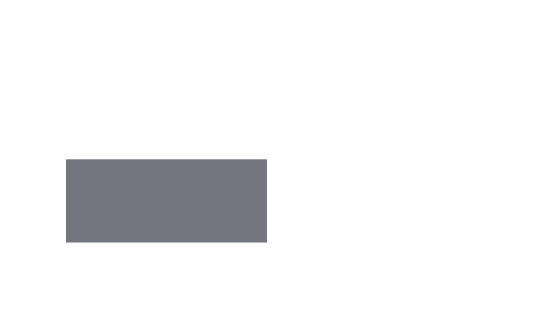

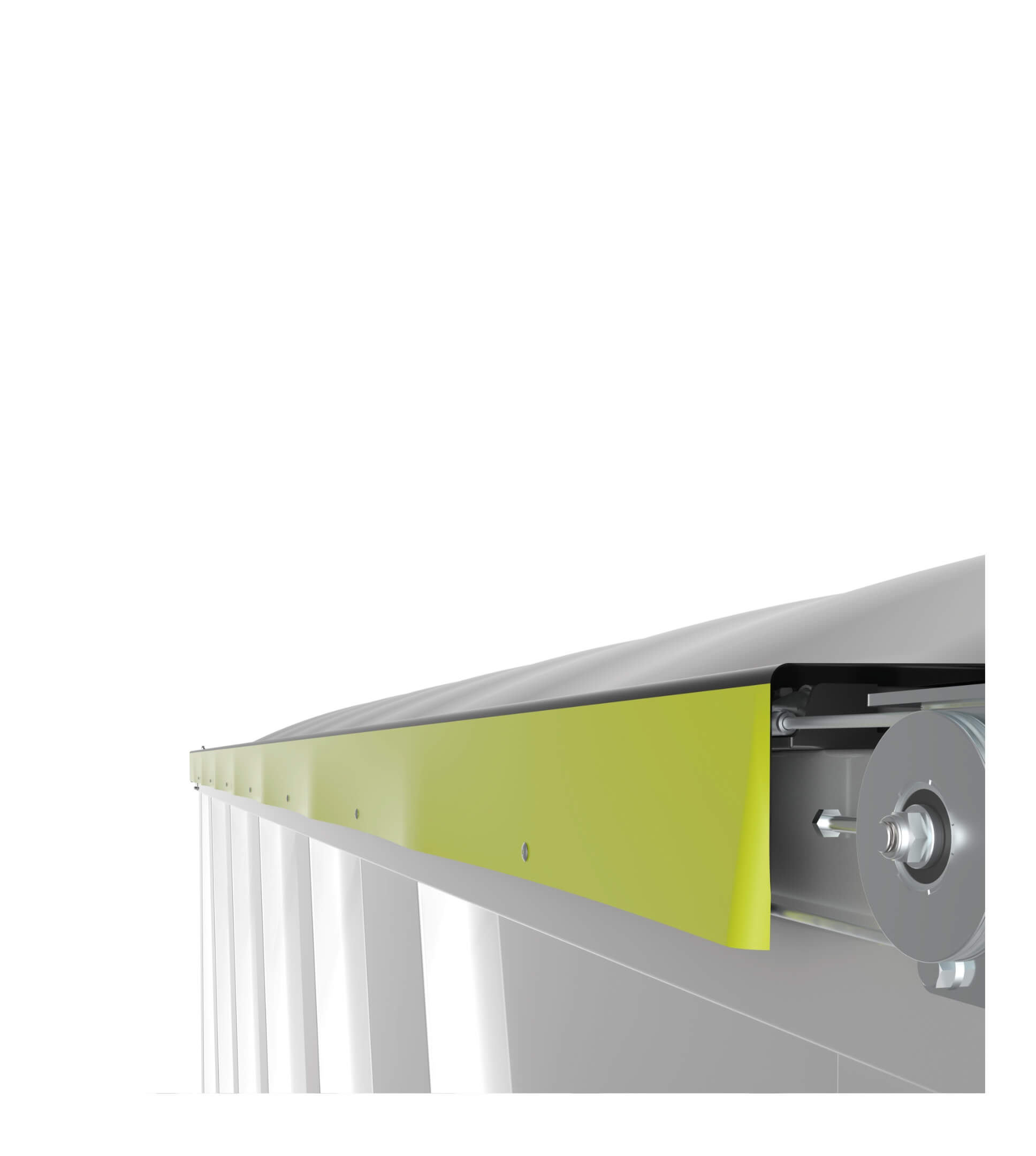

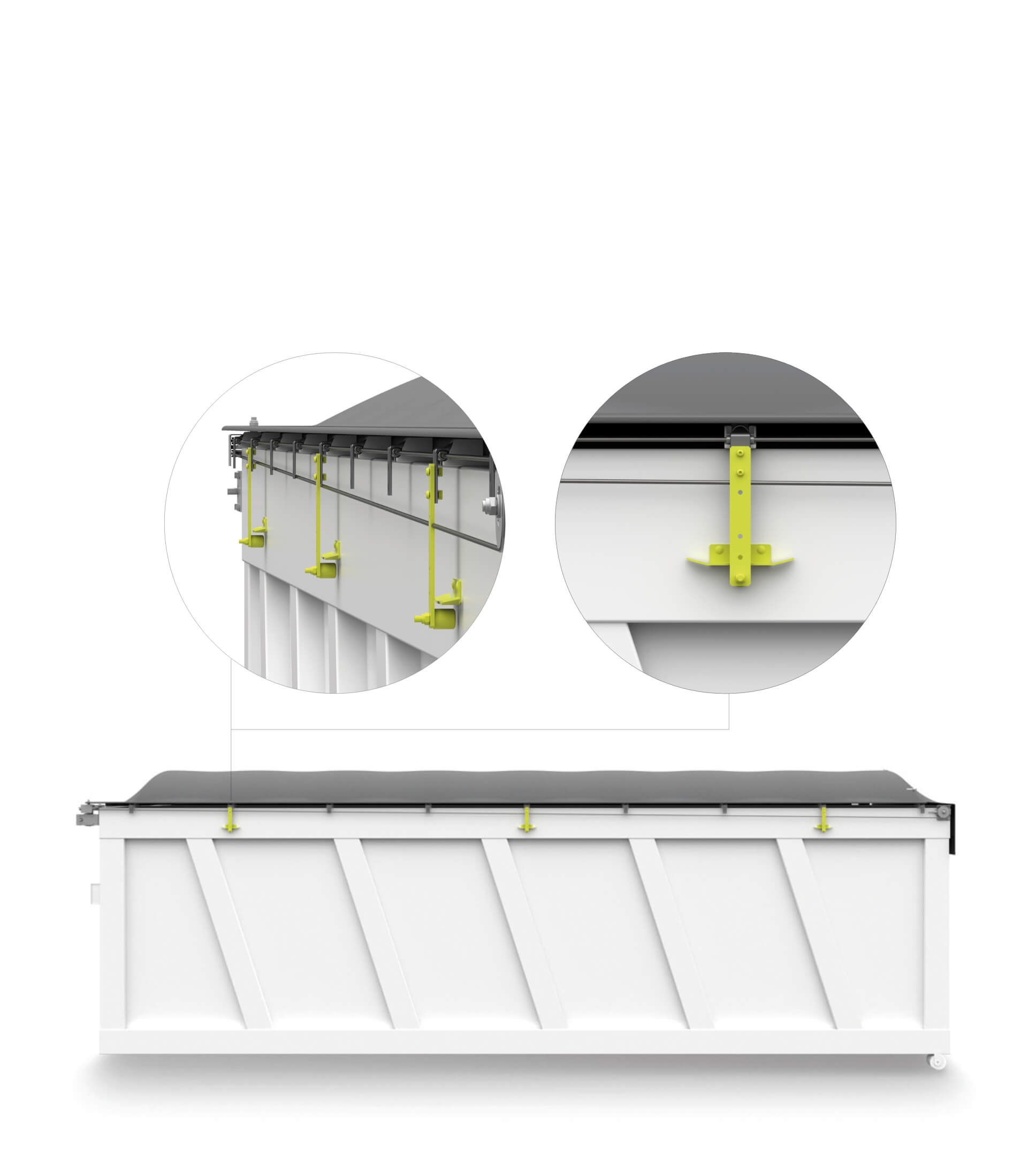

Raised cable cover

One of the best exclusive features of our covers is that you can choose the position of the cables with respect to the upper edge of the side walls. The pictures below show the cable in a raised position, in which the cable remains 13 mm above the edge (standard feature for MCA, Sigillo and Ecotype).

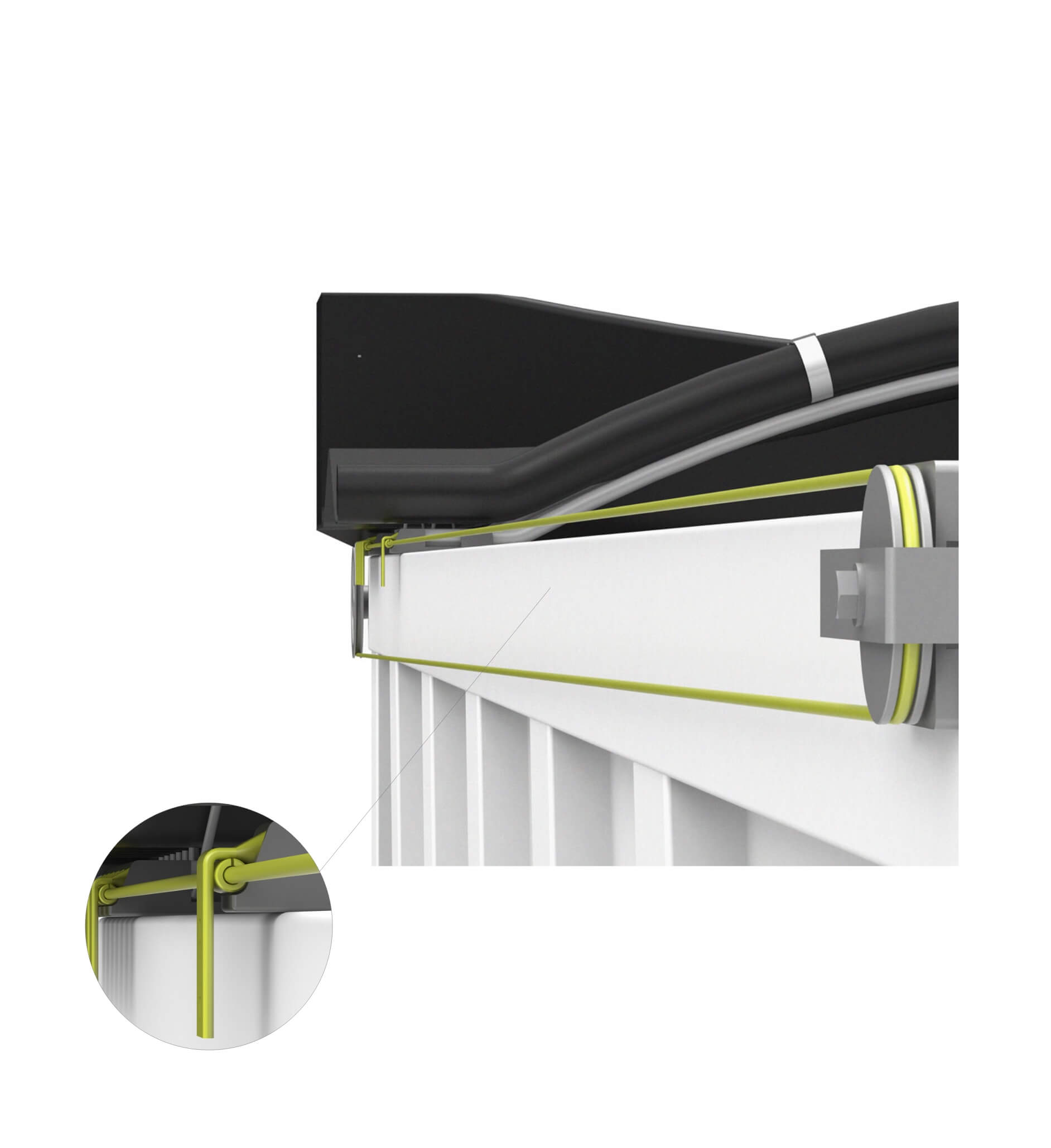

Lower cable cover

Being able to protect the covering’s operating cable results in extended maintenance intervals, and avoids unexpected and costly downtimes. The pictures below show the lower position, in which the cable remains 20 mm below the upper edge of the side walls and is protected against damages caused during loading operations (standard feature of Eletta®).

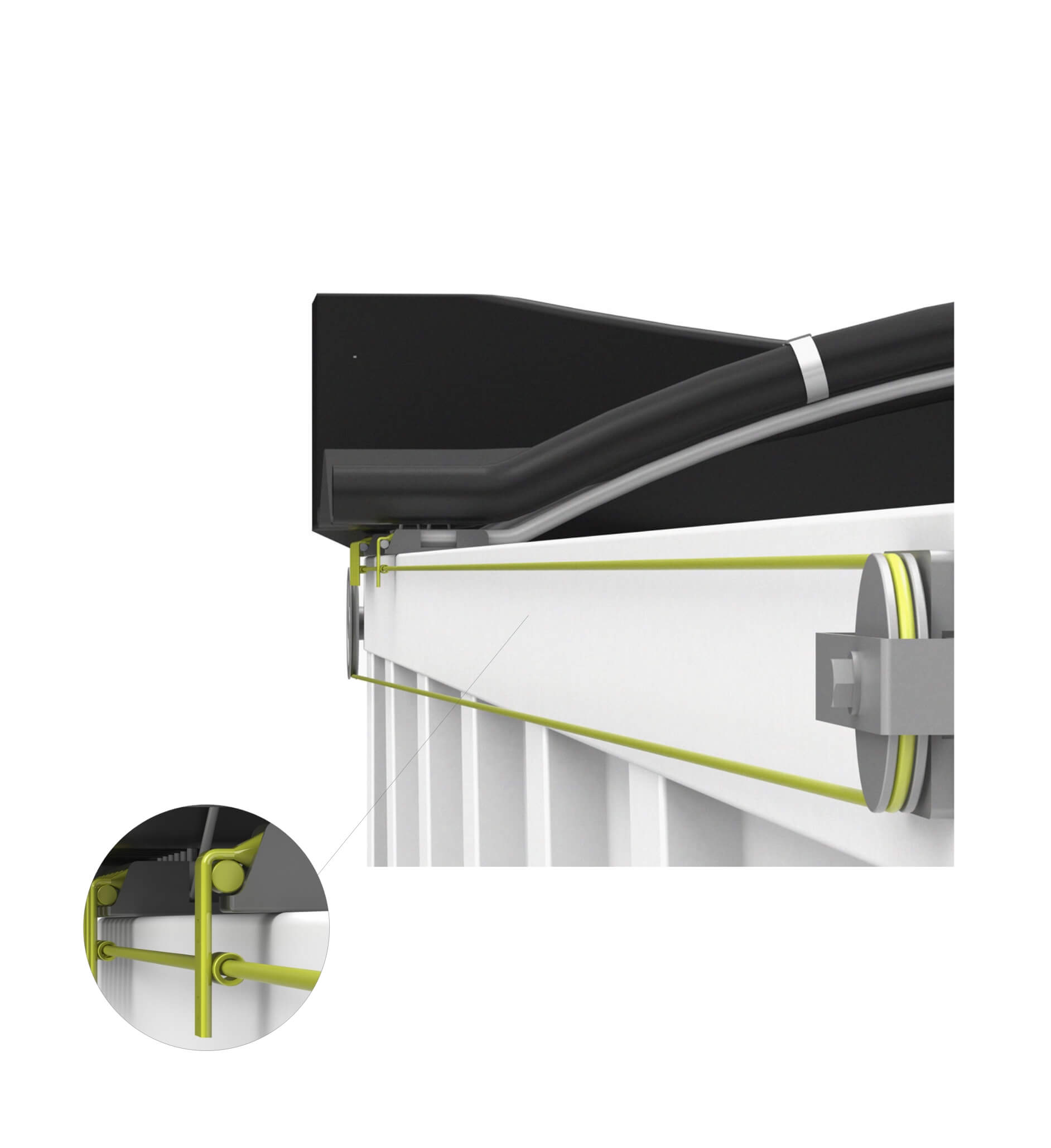

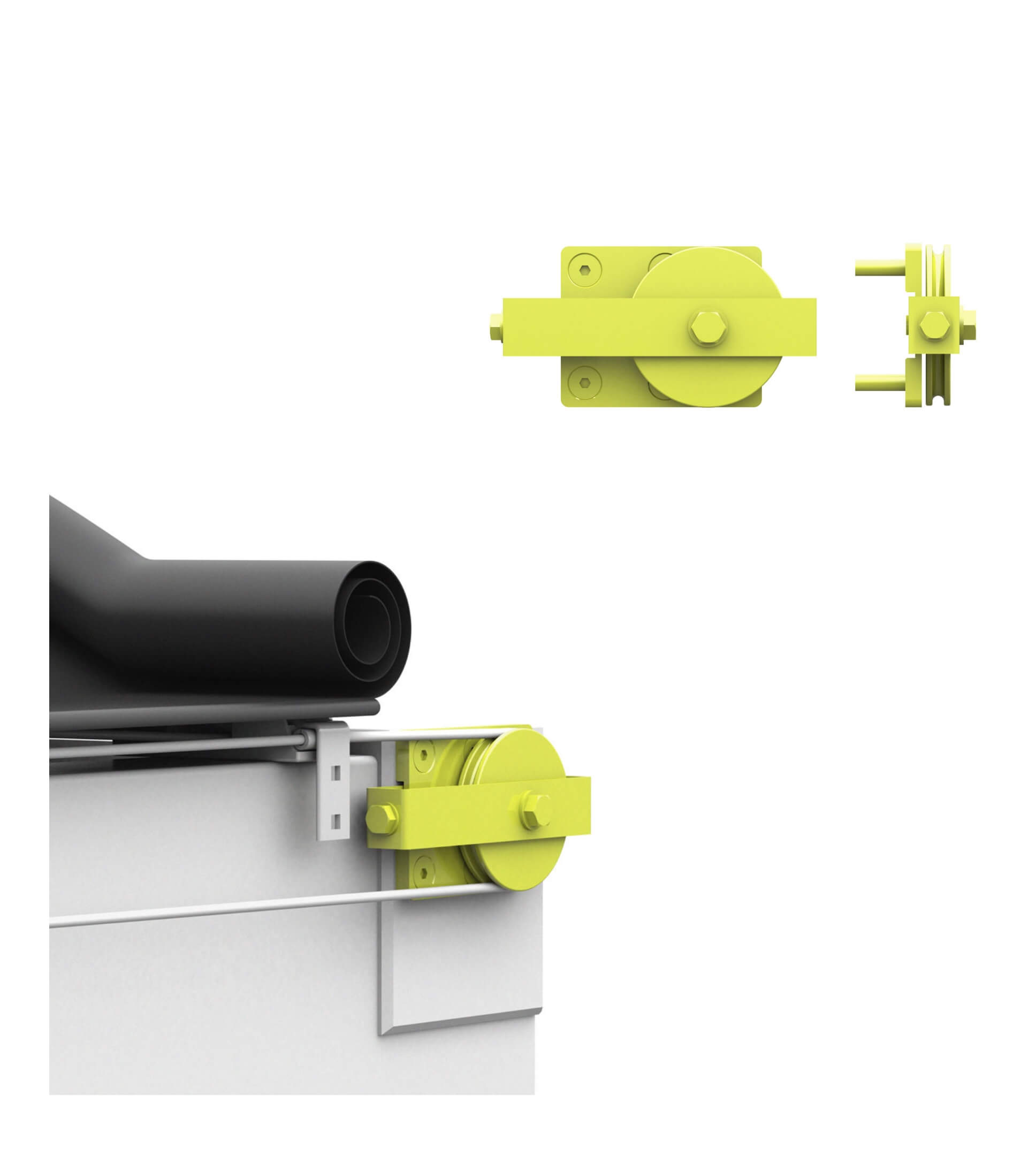

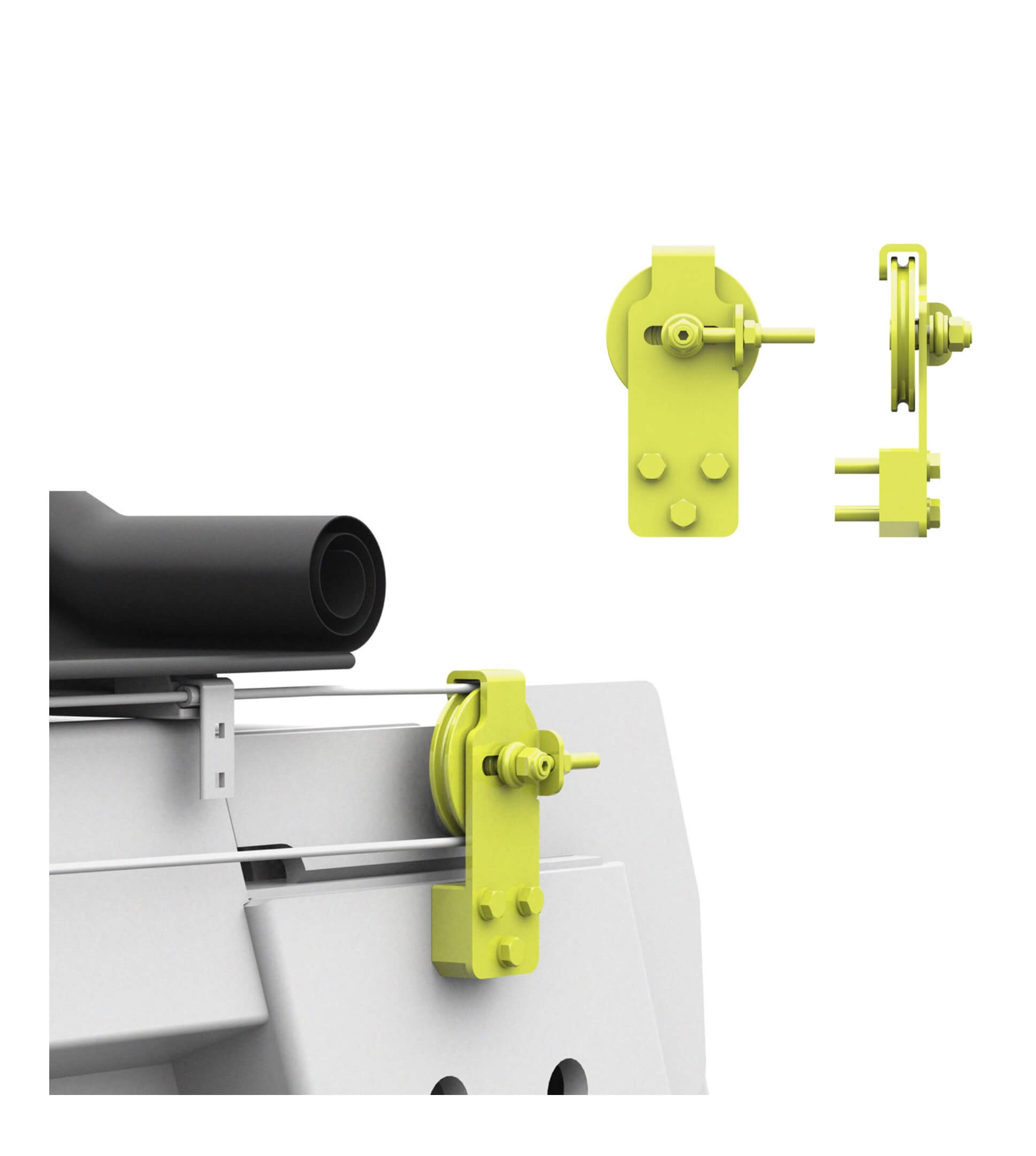

Horizontal tensioning plate

The horizontal tensioning plate, available with Ø70 mm or Ø100 mm pulleys, is easily mounted onto load boxes without specific constraints at the rear. It features an adjustment screw to quickly achieve the correct tensioning of the cable. All the components are made with electrogalvanized steel.

Vertical tensioning plate

The vertical tensioning plate, available with Ø70 mm or Ø100 mm pulleys, is easily mounted onto tipper bodies with hydraulic tailgates. It features an adjustment screw to quickly achieve the correct tensioning of the cable. All the components are made with electrogalvanized steel.

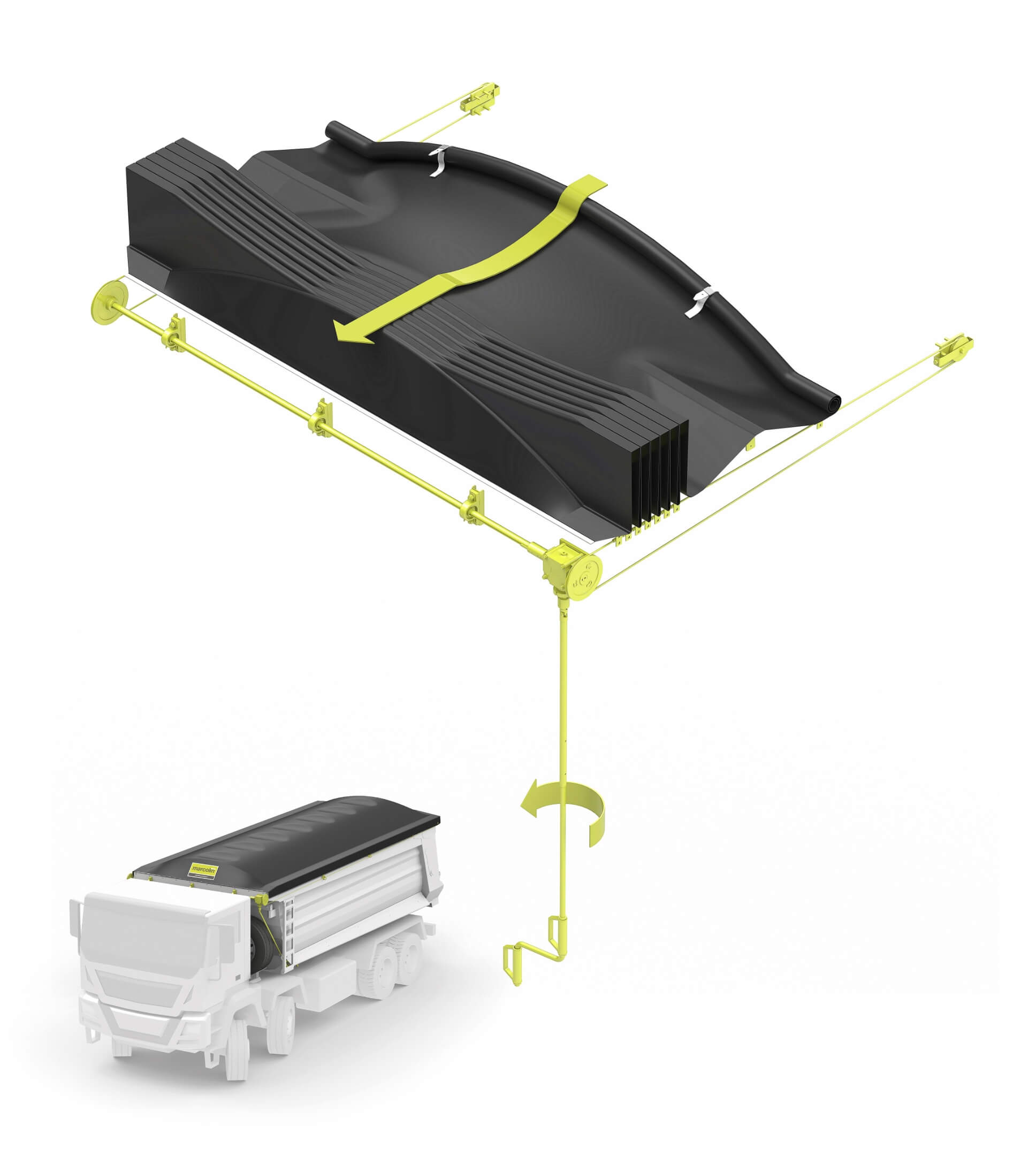

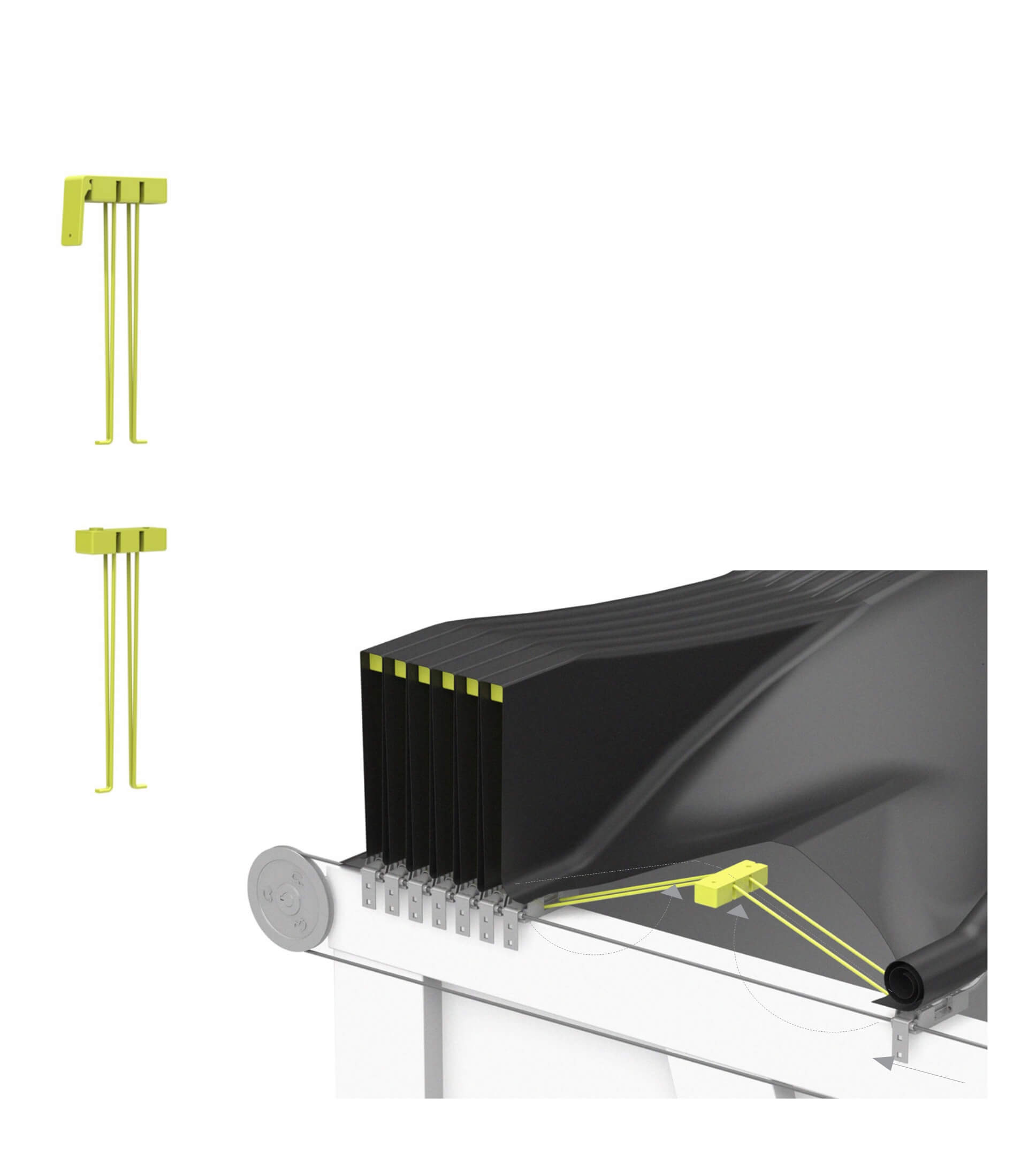

Quick cable release

The quick cable release, installed instead of the “rear tensioning return”, allows you to fully remove the cable from the side walls for easier loading and unloading of two-way and three-way tipper bodies. It can be supplied for one or both sides. Easy to install and quick to use, it is the easiest way to disconnect the cable even during cover maintenance.

Quick cable release from the ground

The quick cable release from the ground allows you to fully remove the cable from the side walls for easier loading and unloading of two-way and three-way tipper bodies while safely remaining on the ground. It is fitted with an adjustment screw for easy tensioning of the cable. It can be supplied for one or both sides. Easy to install and quick to use, it is the safest way to disconnect the cable even during cover maintenance.

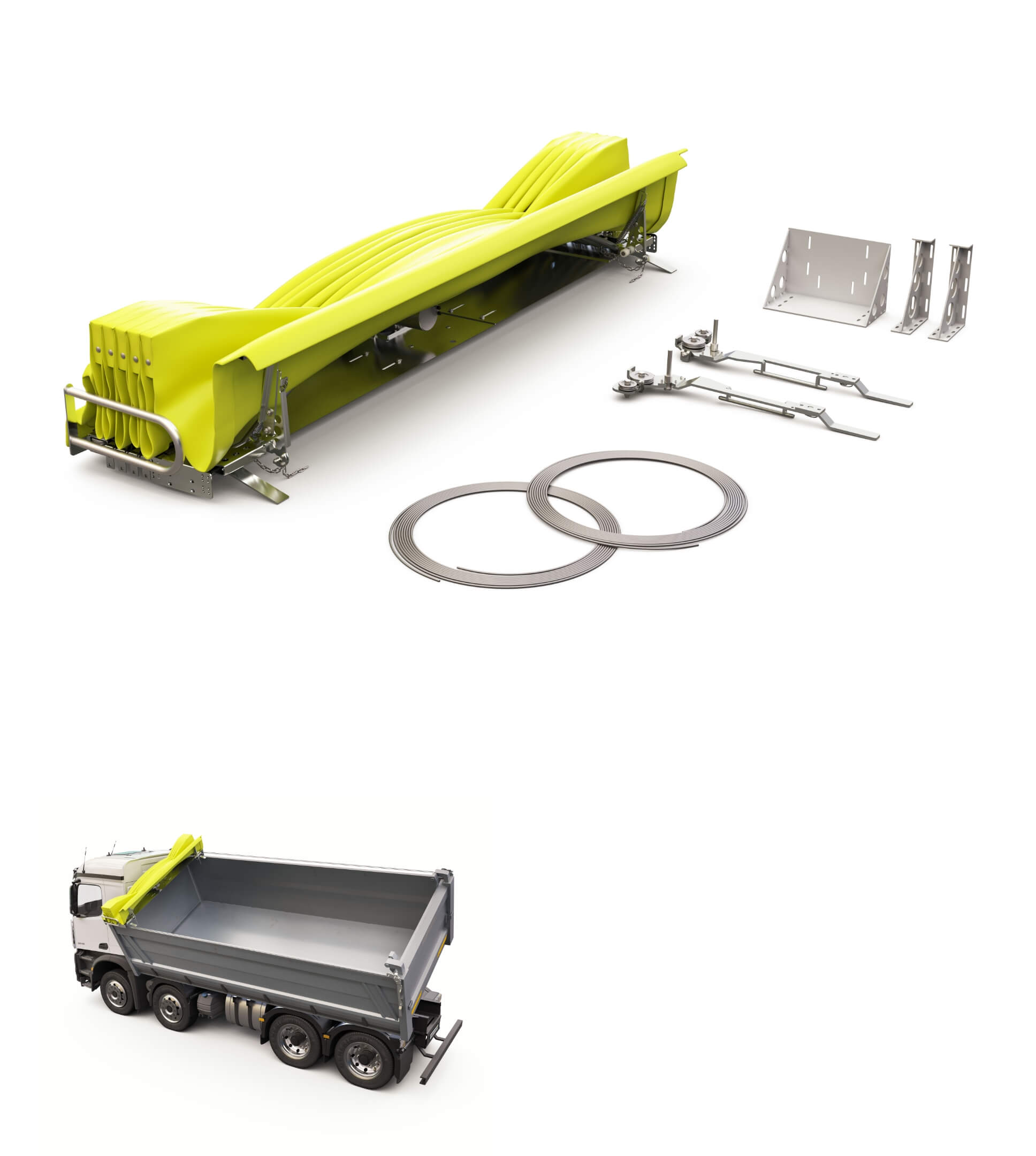

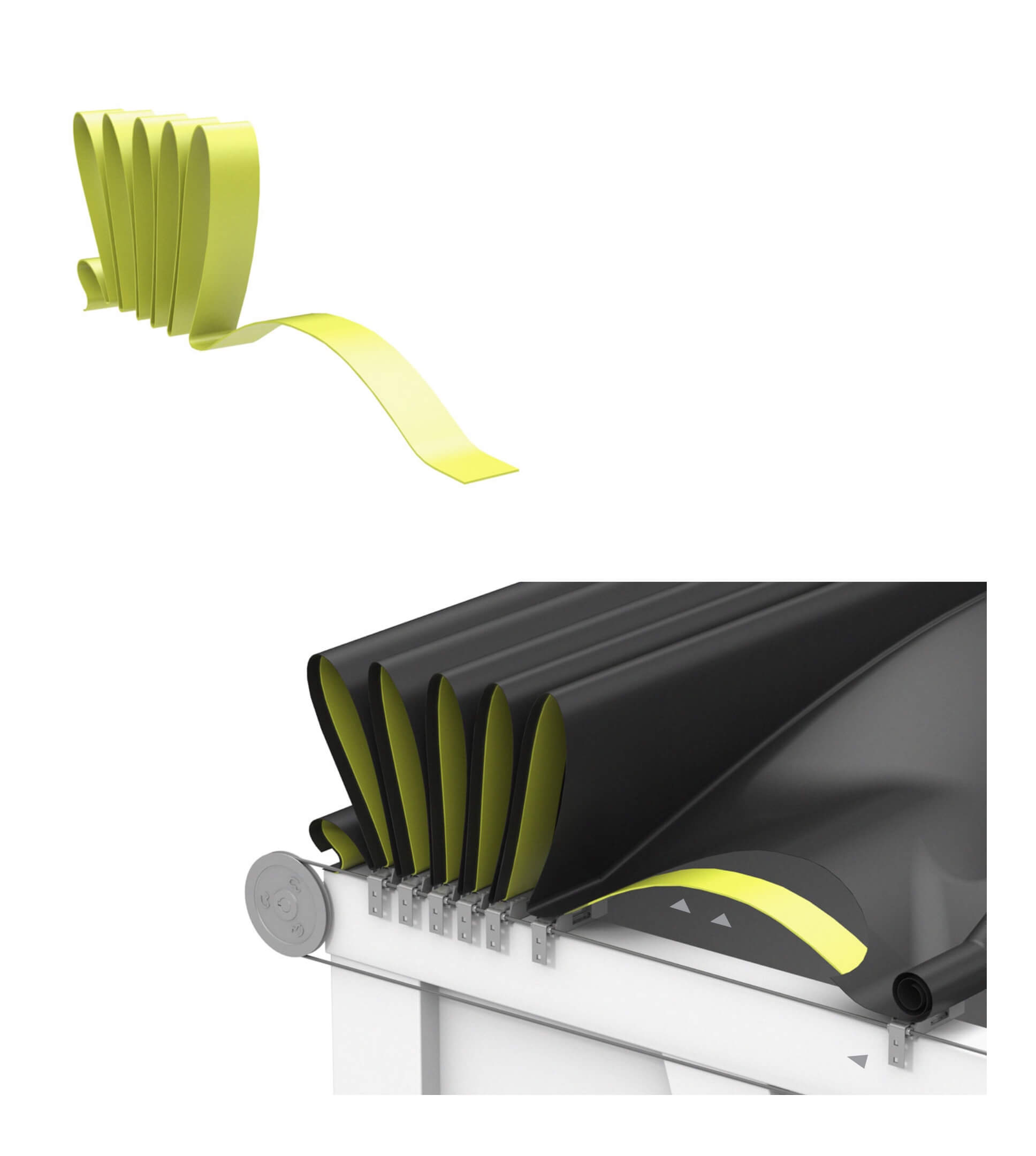

Compass-type tarp lifting supports

When opening the cover, the tarp must be lifted and folded correctly so as not to drag inside the load box where it can become dirty or be damaged by the load. Our compass-type supports have been designed and built to perform this task automatically and to last over time. They do not require any maintenance and, in case of damage, their replacement is quick and simple.

PE profile tarp supports

This extremely flexible white HDPE profile is inserted into a sleeve running the entire length on the sides of the tarp and can be used as an alternative to compass-type lifts to meet the most varied functional requirements.

Side flush cover

Custom-made tarp with reinforced edges.

Sealing cover

The hermetic tarpaulin ensures high load protection from weather conditions and dispersion, thanks to the sealing side bands between the body and the cover. Custom-made and realized with perimeter reinforcements and riveted fastenings, to provide excellent stability and reduced noise during transport.

Automatic “L” hooks

The automatic windproof lashing system with L-shaped hooks firmly secures the tarp to the load box. During closure, the L-shaped hooks engage automatically with the eyelets mounted on the side walls of the load box. This prevents the lifting of the tarp while travelling or in case of strong winds.

The windproof system with retractable fasteners is designed for three-way and two-way tipper bodies.

The automatic fasteners lift during the folding of the body, prevent interference with the opening of the sides. Upon closing, the automatic engagement into the U-Bolt ensures secure fastening of the tarp, preventing lifting during transport or in strong wind conditions.

Swinging hooks

The windproof lashing system with swinging hooks secures to the side rails, if present, or to Z-guides , and holds the cover in place along its entire length, even when open. Designed for use on bodies that bulge under full load, it adapts to all vehicles operating in high-wind areas.

Roller-type hook

The windproof system with POM roller hooks secures the cover to the load box when it is closed. The vertical position of the roller is adjustable to fit on load boxes with upper edges of any shape.

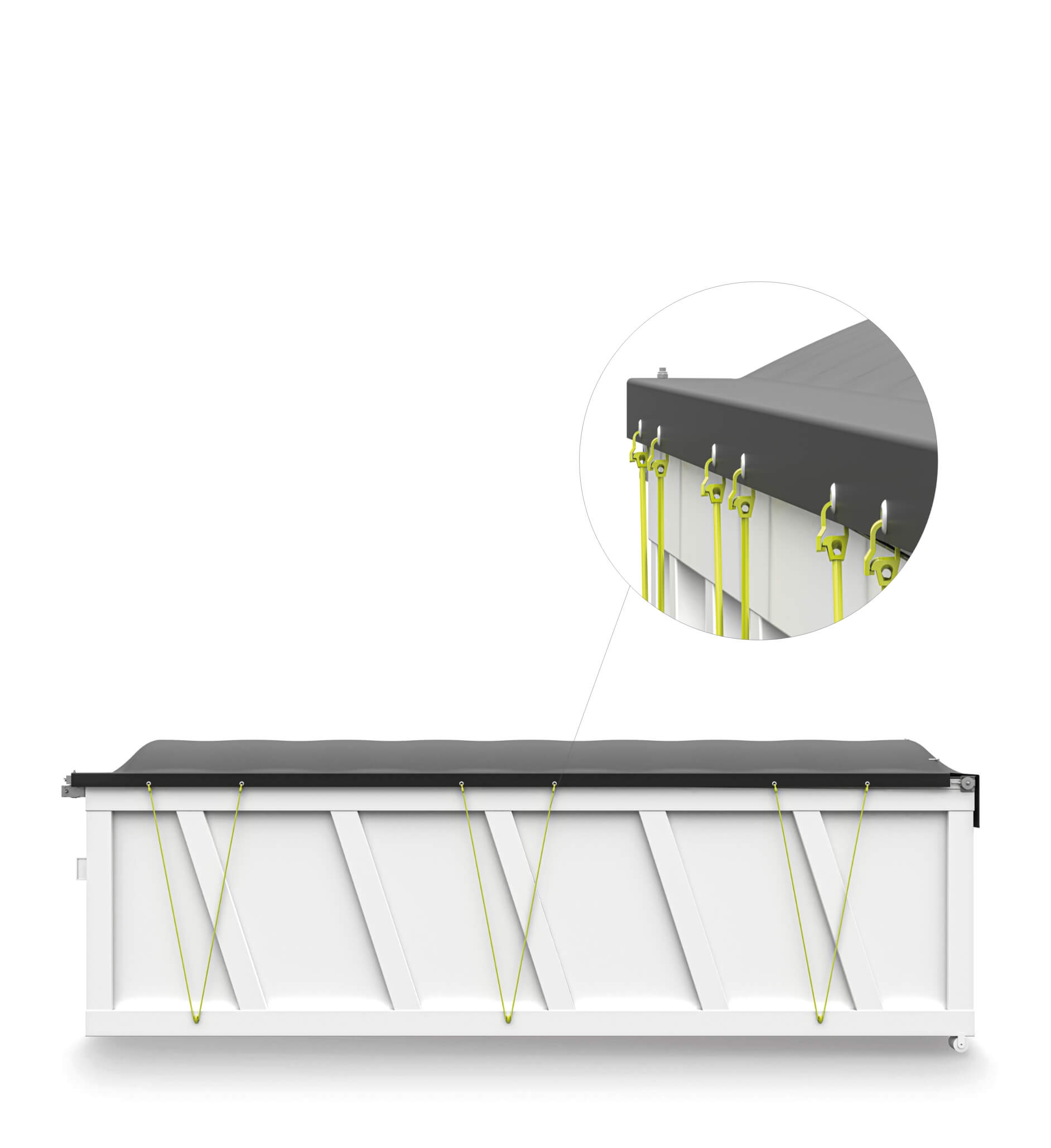

Safety elastic ropes (hooks on bow foot)

The windproof system with elastic ropes and galvanized steel carabiners ensures quick and secure fastening of the cover in closed and open positions. The elastic ropes, anchored to the bow feet, provide hold and durability, integrating with the supporting structure composed of bows and lifts. The number of elastic ropes varies according to the length of the body and the cover configuration.

The windproof system with elastics fixed to the eyelets on the side flaps allows for quick and secure lateral fastening of the cover using a standard kit composed by high-strength plastic cobra fasteners, carabiners, elastic ropes and cords. The number of components varies according to the length of the body.

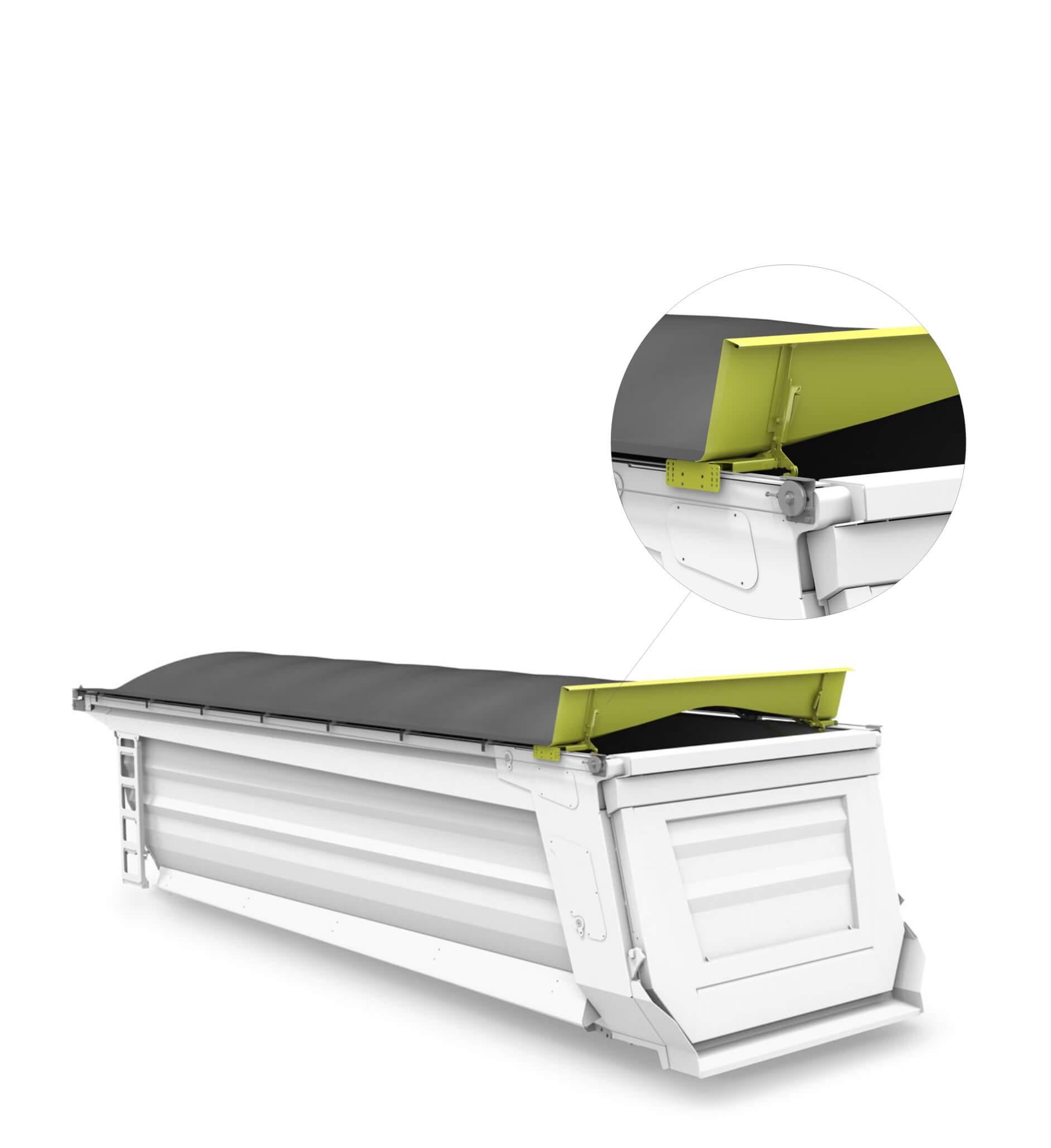

Smart automatic rear closure

The SMART flap is a system that enables the automatic closing of the cover at the rear of the load body, ensuring greater convenience and safety during use. It is easy to install and stable during transport, with an optimised design for greater versatility and compatibility with a wider range of load bodies.

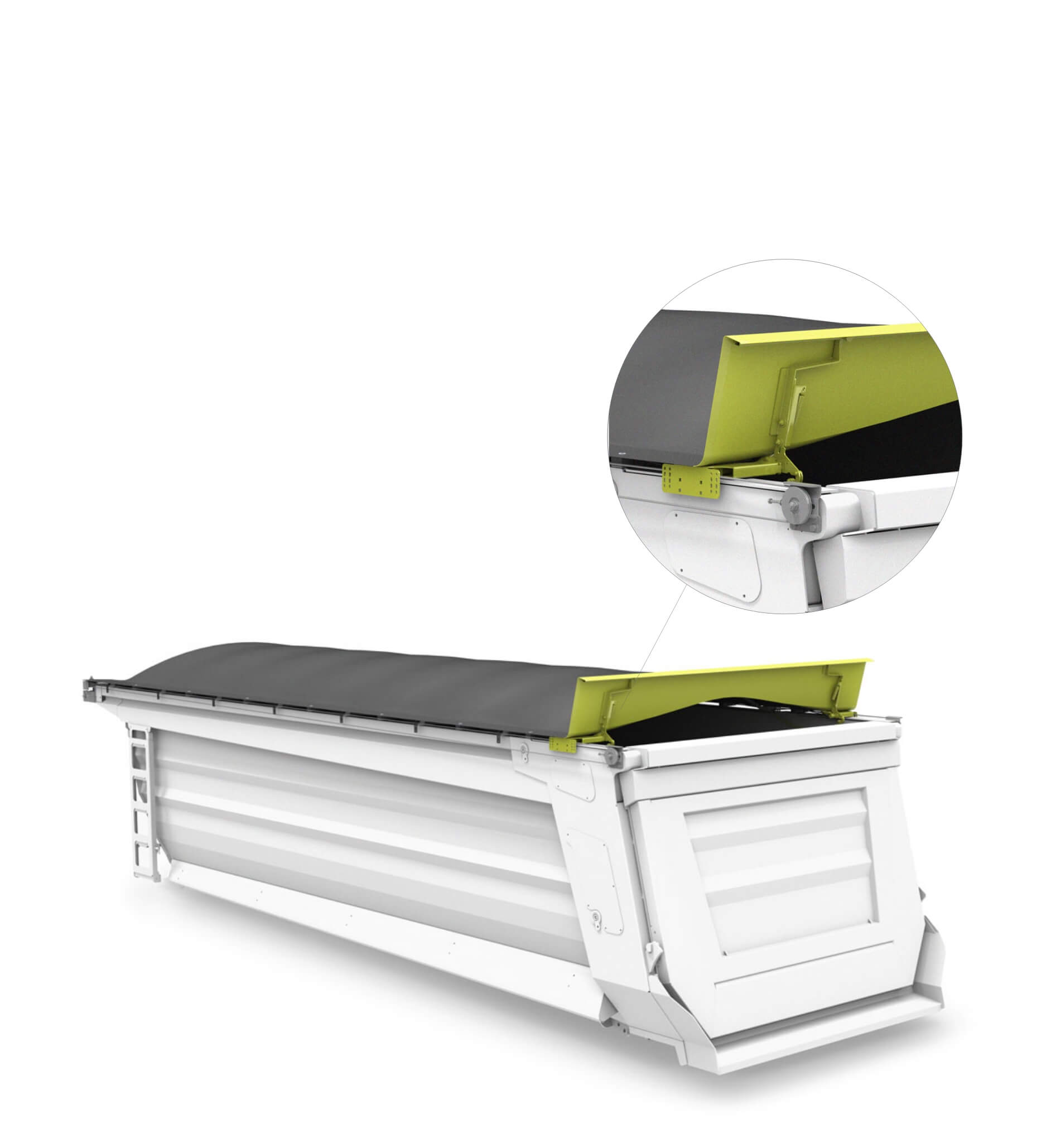

Smart automatic rear closure with angled arms

The latest version retains the well-known ease of installation and stability in transit while optimising the design to enhance versatility and fit a wider range of load bodies. The angled rods version prevents undesirable interference with tailgate mechanisms.

Roll down flap

The closing system features a manually rollable tarp for the final section (standard length: 800 mm). secured to the last bow with three straps.

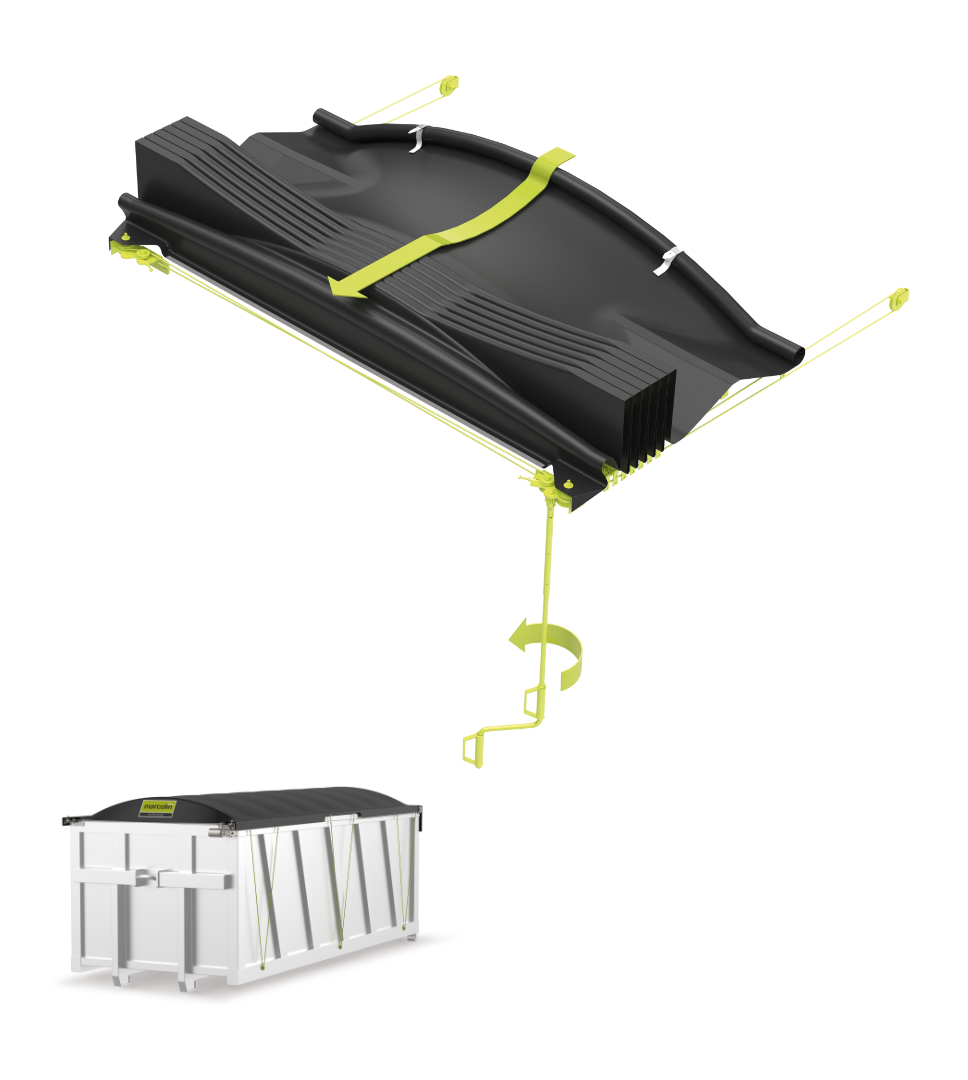

Rollplanner

Closure system ideal to achieve clearances greater than 500 mm. It consists of a tarpaulin that can roll up automatically using preloaded springs located in its final section. It is rolled down manually using a pull string.

Hard closure

Closure system with fixed tarp, with vertical drop on last rear bow.

Zero roll down flap

Closing system that keeps the opening on the final rear bow.

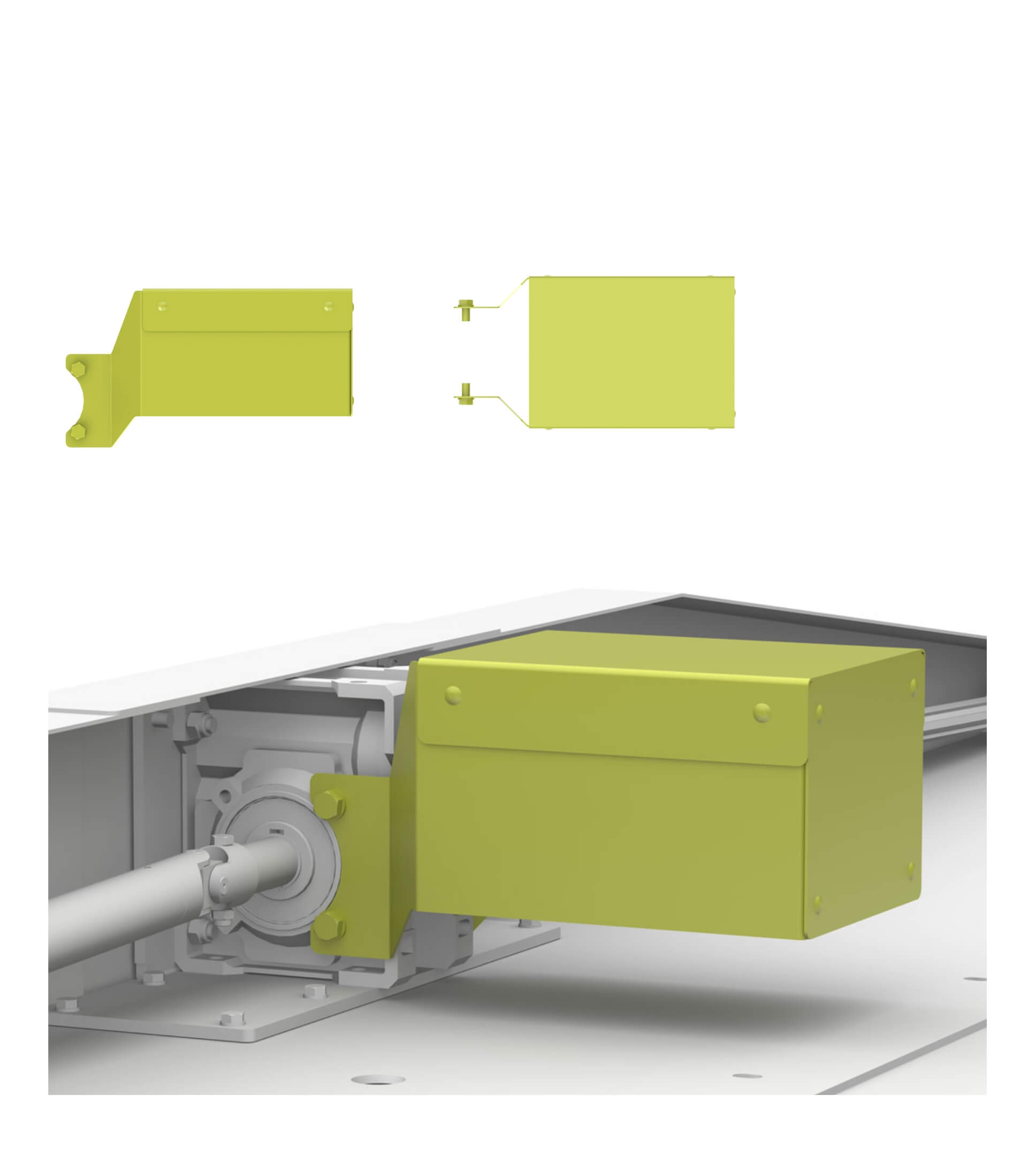

Protective case for Eletta® motor

This case has been designed to provide the most effective protection to the Eletta® motor against debris, dust and any interference with the load in general. It can be installed quickly and easily on all covers, both new and older, using the existing fixing holes on the gearbox.

Wear protection for pads

The robust, stainless steel pad wear protections have been designed to prevent the wear of the sliding pads, especially for covers used on load boxes with sharp side edges (e.g. rock breakers).

in your hands

kitai is the only product in the industry that uses 2.4 | Half Duplex technology, enabling two-way communication between control unit and remote control, and providing continuous feedback to the user for unmatched safety and consistent performance.

Looking for quick answers to common questions about our products? Here you will find all the information you need!

Marcolin Service Point

Are you a Workshop or one of our Service Points and would like to receive more training on Eletta® and other products? Contact us for more information.

Transport coverings for SEMI-TRAILERS, DUMPERS, THREE-WAY TIPPERS, AGRICULTURAL TRAILERS?

Discover the most suitable solutions for each configuration.